Certified GCC LaserPro Spirit GLS 40+ Watt Laser Engraver, SN: XXXXXX ... The GCC LaserPro Spirit GLS is the flagship model of the award winning Spirit line of laser engravers. In succession to GCC LaserPro's worldwide accolades features. This Used Certified model comes equiped with a Synrad 40-watt CO2 Laser Tube.

* Free Labor\Mainternance at Jorlink-HQ Depot Repairs for ninety (90) days.

CLICK HERE FOR MORE INFO

| |

|

|

|

|

RoHS Compliance

All GCC products are RoHS-compliant (the European Parliament Directive 2002/ 95/ EC, Restriction of Hazardous Substances) and lead-free (pb free). GCC will continue to concern and provide environmentally friendly products to protect the earth for our further generation.

|

|

|

DuraGuide

Systematic and reliable motion system embedded with strong mechanical framework, reinforced Kevlar belts, and accurate servomotor control technology to deliver superb output quality under rapid movement.

|

|

|

Closed-loop DC Servo Technology

A Closed-loop DC servo motor can deliver greater continuous shaft power at higher speeds than a stepper of the same frame size. In addition, It can also give far greater accuracy due to the continuous movement, instead of constant stopping and starting. GCC LaserPro high speed closed-loop DC servo motor technology guarantees precise and fast carriage movement with exceptionally accurate outputs.

|

|

|

SmartCENTER™ (Patented)

The super user-friendly SmartCENTER™ function helps end users to easily and automatically locate the center point of objects of any shape vastly eliminating tedious setup time.

Full size video

|

|

|

Astonish 3D Engraving

GCC LaserPro integrates laser firing control and image processing technology to create a 3D engraving function, the laser system assigns up to different laser powers to 200 levels of grayscale in the image to make the spectular 3D effects with different slopes

|

|

|

TrueImage™ Engraving Technology (Patented)

Patented TrueImage feature smoothes the image engraving edge automatically by employing a unique laser firing algorithm to present image engraving in its most vivid form.

|

|

|

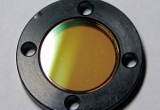

Real Pointer Alignment Feature

Extra beam combiner to align red pointer with laser beam, What You See is What You Get.

|

|

|

Rigid and Reliable Construction

Rigid and stable chassis construction ensures consistent output quality under high speed movement.

|

|

|

SmartACT™ (Patented)

Ground breaking technology that reduces the ramping process and job running time to boost productivity.

|

|

|

Key Switch & Emergency Stop

Key switch safeguards the machine from unauthorized use. Prominent emergency button located on the top of the machine allows operators to stop the laser and the motion carriage immediately to provide a safe operating environment.

|

|

|

SmartLID™ (Patented)

An innovative lid that opens from both ends allowing easy access for daily maintenance.

|

|

|

SmartLIGHT

Built-in LED light module illuminates the working space and makes every engraving detail easy to see.

|

|

|

SmartPIN™ AutoFocus (Patented)

The plug and play probe design makes focusing a one-touch process and provides the accuracy and precision required for optimum quality in the lasering process.

|

|

|

Intuitive Control Panel Interface

A control panel with coherent hot-key design and graphical icon displays that allows you to change laser parameter settings, set jobs to repeat unlimited times, queue jobs, delete jobs, and more.

|

|

|

Drag-N-Play

An exceptionally innovative and user-friendly feature based on servomotor technology simplifies operations and shortens setup time. Simply hand drag the lens carriage to the desired position to be engraved and press the start button to commence job.

|

|

|

Pass-through Front & Rear Doors

Convenient front and rear door open design enables loading of extremely long working pieces with ease and extends business flexibility.

|

|

|

Extra large working Area

Extra large working area extendable to 38" x 24" (960 x 610 mm). The spacious platform allows jobs that require large working space.

|

|

|

Innovative Windows Driver

Directly output from familiar designing software like Illustrator, CorelDraw, AutoCad through GCC LaserPro unbeatable Windows driver featuring powerful functions such as SmartCENTER™ , Defocus by pen, Programmable Air Assist TrueImage, Vector Path Optimization and more allow easy set up and achieve marvelous output quality.

|

|

|

Programmable Origin Modes

Easy-to-use multiple position modes allow the operators an effortless way to setup a job with Drag-N- Play. Repetitive workflows can be drastically simplified by relocating the origin position to any desired location.

|

|

|

Built-In Networking Connection

Network connection enables multiple laser engravers to be operated by one PC and multiple PCs to share a single unit of laser engraver. The Ethernet port has made data transmission easier and faster for GCC LaserPro users using network connection. Free your designers with great flexibility and maximum machine versatility...MORE

|

|

|

Automatically Switch Between Laser Tubes

GCC LaserPro dual-laser technology allows users to specify laser types per different color pens with Windows driver setting. The laser system will then switch automatically between laser tubes within one job. No optics change or manual adjustment is needed when switches happen between laser firings.

|

|

|

Removable Exhaust Duct

Easy access for cleaning dust accumulated in the exhaust duct on a regular basis helps maintain the ventilation efficiency and job quality.

|

| |

|

|

| |

|

|

|

Return to top of page

Description: Spirit GLS-40 Watt+ Sealed CO2 Laser (SGLS-40v)

Work Area: 38" x 24" (965 X 609mm)

Part#: MGL-SGLS40

Features Included: Red Pointer, Air Assist Ready , DC-Servo Motors, Drag-N-Play, Smart Center, Pass-Through Front & Rear Doors, Long-Life High-Speed Rail\Bearings, Automatic Focusing of Z Axis with an Expandable Work Area: Expandable to 38”x24” (965x609mm)

Included with this unit:

(1) Three (3) Months Jorlink Depot Warranty

(2) One (1) Year 365-GoldCare Phone Support ($695)

(3) Free Demo Accessories (Honeycomb Table, Air Compressor)

* Warranty: Three (3) Months Parts Warranty for the exception of laser tube. Jorlink will pay for replacement parts and pay one way to client. Client is responsible for replacement of parts and for non-consumable parts returning defective parts to Jorlink. If a technician is required on-site client will be responsible for a Flat Fee of $495 for the day during the warranty period plus any major travel expenses (air\extended stay).

** Setup\Install is recommended from ½ Day to Full Day ($850 or $1,200 for Local clients. Airfare may apply for clients over 500 miles).

*** Free Pick-Up at Jorlink Greensboro-NC Facility or Shipping Available, Freight Charges Apply (Approx. $850+ USA Continental).

**** Satisfaction Guaranteed- 30 Day Trade-in period for upgrade credit to a new machine if client decides to upgrade unit.

Other Conditions:

• Synrad 40+Watt Metal Tube

• Work Area: 38 x 24” in. (960 x 610 mm) with User Programmable Origin

• Windows Base Print Driver, Open Architecture Electronics allowing many graphics program such as EngraveLab Laser, CorelDraw, Adobe, AutoCAD

• Motion System with DC Servo Motor

• Pass-through Front and Rear Doors (Optional Interlock Bypass)

• Includes USA II-VI Optics with 2” Lens (Optional 1.5” or 4”)

• RoHS Compliance

• Optional accessories available (EngraveLab Laser Software, Rotary Attachment & SmartPrint Apple Driver)

Web Link: https://jorlink.com/machines/certified-demo-equip

All Warranty & Service activities by either the manufacturer or support services from Jorlink shall be applicable to addresses based in the Continental United States.

For our Warranty, Terms and Conditions, please visit our website or the link below: https://www.jorlink.com/support/documentspolicieswarranties.aspx

DIM's: 868-Lbs 78"Lx49"Wx51"H (FOB Point: Greensboro-NC)

Return to top of page

|

GCC, a global forefront equipment-manufacturing provider in the visual-tech industry, is pleased to announce the new optional Roll to Roll Autofeeder device, available for GCC LaserPro Spirit & Spirit LS.

GCC, a global forefront equipment-manufacturing provider in the visual-tech industry, is pleased to announce the new optional Roll to Roll Autofeeder device, available for GCC LaserPro Spirit & Spirit LS.

The Roll to Roll Autofeeder unit is a superior user-friendly optional item that can be used in tandem with GCC LaserPro Spirit or Spirit LS models to form an automated engraving system when working with rolled material. For instance, if used with Heat transferable material such as PureFlex or SEF heat transfer papers, the laser can produce very exquisite and delicate patterns which can be heat pressed directly without the need for weeding. The Roll to Roll Autofeeder is the essential solution to mass production requirements.

Pass-through Door Switch Module

The Pass-through Door Switch Module is designed to activate the laser when the door is open which conforms the CDRH safety required by FDA.

Aluminum Grid Cutting Table

The aluminum grid cutting table is an ideal pal for laser cutting. It lifts the work piece off the work table from hitting by laser reflection while supports it with reinforced aluminum grid design. The dust and vapor created during laser cutting are then taken away effectively through the grid by down vacuum funnel exhaust. Rather than handling rigid materials, aluminum grid cutting table also helps to fix flexible materials with the aid of down vacuum to keep constant focus distance and consistent cutting result. A clean and better cutting quality is achieved from this technique.

Rotary Chuck

The rotary chuck is a handy …..for engraving on cups, wine glasses, and even spherical objects with tilt angle. In addition to the standard X, Y, Z axis, the rotary Chuck allows for a fourth axis which rotates the object 360° to allow for engraving on cups, wine glasses, and even spherical objects. The diameter range of the to-be-engraved object is 0.5mm to 120mm and the max. length of the object is 410mm. Its maximum weight should not exceed 4kgs.

*Please note that the Rotary Attachment is not able to work with AAS module at the same time.

External Interface Control Board

The External Control Interface Board is an optional item that allows users to set up GCC laser machines for communication with external devices such as odor reduction units, robot arms and others via a 5V or 12V signal to form an automatic production line. Another useful practice applies in certain working environments when users are required to set up an extra remote interlock control or when laser machines are allowed to be switched off if a security device is triggered.

Multi-purpose Integrated SmartBOX™

The removable drawer design facilitates the cleaning of the SmartBOX™ making it easy for users to remove fallen debris simply by pulling out and sliding the drawer back in place after cleaning. Various set up choices, such as tipped bars/honeycomb table/platform, and easy transformation conveniently accommodates your work requirements.

External Signal Indicator

The indicator will flash to signal the end of job process and is ideal for working environment where audibility is weak.

SmartBOX™

An innovative technology that integrates the ventilation box with a honeycomb table or Aluminum grid cutting table. The result is not only a precise cut with sharp edges, but also a clean laser table to work on.

Rotary Attachment

Allows the laser system to perform at another level! By using the rotary attachment, engraving on cylindrical or round objects is now possible. This option uses a fourth axis to rotate your object 360° to allow engraving on cups, wine glasses or even a baseball with two types of conical fixture available. The minimum/maximum diameter and length of the working object is 90/180mm and 450mm respectively. Its maximum weight should not exceed 4kgs.

*Please note that the Rotary Attachment is not able to work with AAS module at the same time.

Dust Prevention Window

When the laser system is on duty, it will bring a lot of dust result from the material and it will contaminate the lenses and mirrors. Dust Prevention Window can keep lenses and mirrors clean to promote longer laser life and increase the effect of air induction.

Purex Fume Extraction System

GCC teams up with a UK company to offer the Purex fume extraction unit for its full-line LaserPro laser engraving and cutting systems. These Fume Extraction Systems are specifically designed to prevent personnel from inhaling hazardous fumes and dust generated during the process. Applicable to all GCC LaserPro engravers, the Purex Fume Extraction System represents the latest invention in the exhaust extraction and smoke reduction technology for all types of applications. Noise-free operation, high vacuum capacity, compact design and long life expectancy are just a few of its outstanding features. Powered by a maintenance-free, continuous-running turbine, the Fume Extraction System, which is CE-compliant, ensures personnel safety and legal compliance.

Air Compressor

A specially designed Air Compressor for laser engravers, by using an oil-less diaphragm, you help eliminate the harmful and damaging side effects of moisture on the laser optics. Also, provides the optimal air pressure your laser needs to blow away vaporized particles and helps prevents overheating. A must to keep lenses and mirrors clean to promote longer laser life.

SmartGUARD™ Fire Alarm (Patented)

Laser cutting and engraving operation using the SmartGUARD Fire Alarm assures optimum safety. When there is a malfunction, the alarm system will be active and shut-down the operation system immediately.

Honeycomb Table

The honeycomb table is an ideal tool for laser cutting, especially when cutting materials into small pieces. It lifts the work piece off the work table from hitting by laser reflection while supports it with honeycomb cell design. The dust and vapor created during laser cutting are then taken away effectively through the honeycomb cell by down vacuum funnel exhaust. Rather than handling rigid materials, honeycomb table also helps to fix flexible materials with the aid of down vacuum to keep constant focus distance and consistent cutting result. A clean and better cutting quality is achieved from this technique.

| Spirit GLS |

|

| Work Area |

34 x 24 in. (860 x 610 mm) Extendable to 38 x 24 in. (960 x 610 mm) |

| Max. Part Size (W xL x H) |

All doors closed |

39x25 x7 in. (990 x 635 x 177 mm) |

| All doors open |

39x ∞ x 7 in. (990 x ∞ x 177 mm) |

| Table Specs |

40.3 x 27.7 in. (1025 x 705 mm), Aluminium |

| Dimensions (W xL x H) |

53.7 x 34.6 x 39.7 in. (1365 x 880 x 1010 mm) |

| Laser Source |

40-Watt Sealed CO2 Laser Tube

Powered By Synrad-Made in the USA |

| Cooling |

Air-cooled, Operating environment temperature 15°-30°C (60°-86°F) |

| Drive |

Closed-loop DC Servo Control |

| Maximum Motor Speed |

80 IPS |

| Throughput* |

260.9 in²/ hr (1683 cm²/ hr) |

| Throughput* with SmartACT™ Enabled |

322.1 in²/ hr (2078 cm²/ hr) |

| Speed Control |

Adjustable from 0.1~100% (Up to 16 color-linked speed settings per job) |

| Power Control |

Adjustable from 0~100% (Up to 16 color-linked power settings per job) |

| Distance Accuracy |

0.254 mm or 0.1% of move, whichever is greater |

| Z-Axis Movement |

Automatic |

| Focus lens |

Standard 2.0", optional 1.5", 2.5", & 4.0" available |

| Resolution (DPI) |

Available 125, 250, 300, 380, 500, 600, 760, 1000, 1500 |

| Computer Interface |

Standard printer port and USB 2.0** port |

| Compatible Operating Systems |

MS Windows |

| MCB Controller Memory |

32-MB RAM, Expandable from 64-MB to 32-GB External

|

| Display Panel |

4-line LCD display showing current file name, total working time, laser power, engraving speed, file(s) loaded into memory buffer, setup and diagnostic menus |

| Safety |

Class I Laser Product Complies with EN60825

Class II Laser Product Complies with CDRH |

| Facility Requirements |

|

| Operation Voltage |

Below 40Watt, 100~240 Volt AC Auto Switching;

40Watt and above, 200~240 Volt AC Auto Switching |

| Power Consumption |

2000W - 4400W |

| Air Exhaust System |

External exhaust system is required, one 4" connection on the back of the machine |

*Throughput value represents the Max. number of 8 in. x 10 in. 500DPI raster jobs that can be done per hour.

** File transmission at USB 2.0 Full Speed rate.

Specifications are subject to change without prior notice.

New-Demo GCC LaserPro Spirit GLS 40+ Watt Hybrid Laser Engraver, SN: R55058

* Warranty: One (1) Year Parts Warranty. Jorlink will pay for replacement parts and pay one way to client. Client is responsible for replacement of parts and for non-consumable parts returning defective parts to Jorlink. If a technician is required on-site client will be responsible for a Flat Fee of $495 for the day during the warranty period plus any major travel expenses (air\extended stay).

Satisfaction Guaranteed- 30 Day Trade-in period for upgrade credit to a new machine if client decides to upgrade unit.

All Warranty & Service activities by either the manufacturer or support services from Jorlink shall be applicable to addresses based in the Continental United States.

For our Warranty, Terms and Conditions, please visit our website or the link below: https://www.jorlink.com/support/documentspolicieswarranties.aspx