Solder Air Cleaning Fume Extractors

Air Cleaning for the electronics manufacturing applications require many different solutions. Manual solding fume removal processes at various work stations require a different solution from robotic soldering and production line fume extraction. Air cleaning fume extractors can save on heating and cooling expense over exaust systems. Contact a Jorlnk consultant.

Wave/Reflow Ovens- Energy Savings

Fume extraction offers several unique benefits for exhausting wave and reflow applications. One of the most important is improved process consistency due to our technology to monitor and maintain air flow. Additionally, we provide portability, ease of maintenance and improved energy costs. Using Purex solder fume extraction system allows you to utilise the heat in the winter rather than sending costly air back outside of the building; which will reduce the need for costly air make-up systems on your roof top. We have a solution for your reflow, wave and even solder pot coverage.

We know conformal coating cells are often moved frequently and fumes are a nuisance to those working in the area. In some areas, permitting is also very difficult and costly for this process. We provide machines to deal with fumes from your coating machines and also the curing cells which are attached. Let us help you with the entire process. From coating to curing to off-gassing on drying racks. Harmful and odorous vapours can easily be managed with our filtration while also offering and flexible and easily movable exhaust alternative.

Laser Depaneling

Working with laser processes is our expertise! During the depaneling process particulate and vapours are released from the FR4 material. We offer systems to capture the particulate and the vapours allowing your process to be clean and safe in the workplace while also providing a flexible and portable solution.

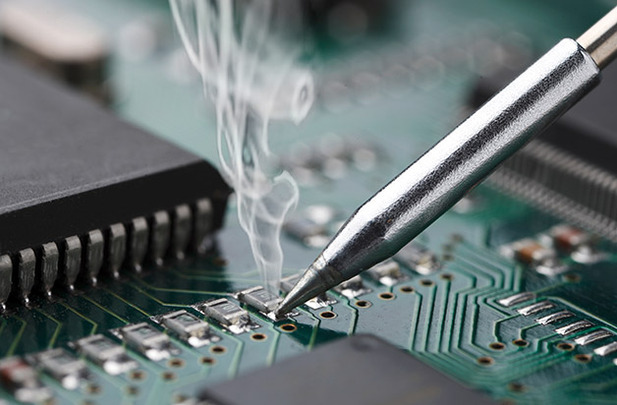

Hand Soldering

Working at close proximity to solder and flux fumes, workers need the best protection. With ongoing health concerns such as chronic asthma, acne, and other issues it is critical to provide a safe work environment. We offer a full line of solutions with machine sizes to extract from 1 station to over 20! Also offering a full line of capture options including lighted stainless-steel arms to clear hood cowls and cabinets.

Selective / Robotic Soldering Air Cleaner

As processes in through-hole technology become more automated, selective and robotic soldering become more popular. Our systems are portable and flexible enough to deal with the enclosed selective solder machines as well as the open-air soldering robots. Let us help you find the right solution.

The soldering process itself can produce some, if not all, of the fumes in the list below. These fumes can cause occupational asthma, long term carcinogenic diseases and other serious complaints. The result of these illnesses can be expensive compensation claims from employees, long term sickness and poor employee relations, plus heavy penalties from enforcement agencies.

Substances Removed:

|

Processes Requiring Fume Extraction Include:

|

- Carbon Monoxide

- Volatile Organic Compounds (V.O.C)

- Abietic Acid

- Pimaric Acid

- Aliphatic Aldehydes

- Hydrochloric Acid

- Isocyanates

- Isopropyl Alcohol

|

- Reflow Ovens

- Selective Soldering

- Wave Soldering

- Hand Soldering

- Rework, Repair and Education

- Laser & Robotic Soldering

- Underfill

- Conformal Coating

- Printing

- Solvent Applications

- Purex Solution

|

Purex fume extraction systems are designed in conjunction with some of the worlds largest Contract Electronics Manufactures and Equipment Providers to help:

- Prevent damage to production machinery.

- Reduce downtime for cleaning and maintenance

- Protect personnel from harmful fumes.

- Reduce product rejects due to poor production performance.

- Maintain a constant extraction rate to ensure stable temperature profiles.

- Deliver long filter life.

- Interface with the production equipment

|

After initial consultation Purex engineers can visit a site free of charge to carry out a survey and to suggest suitable designs and solutions.

Contact us for help choosing the right Fume Extractor for your needs.

Filter finder chart

|