Phenolics Vs. Innovative Plastics Impact Modified Acrylic

Phenolics Vs. Innovative Plastics Impact Modified Acrylic

IPI’s ultimate laser engraving series, 55 stock products, in front and reverse engravable versions and a variety of colors and looks. UV-stable for exterior as well as interior use. Laserables have the most durable micro-surface in the industry, . 0025”, which allows user to laser engrave and/or profile cut with superior ease and quality.

UL Certified

The Laserables Series Laserables - Front Engravables.

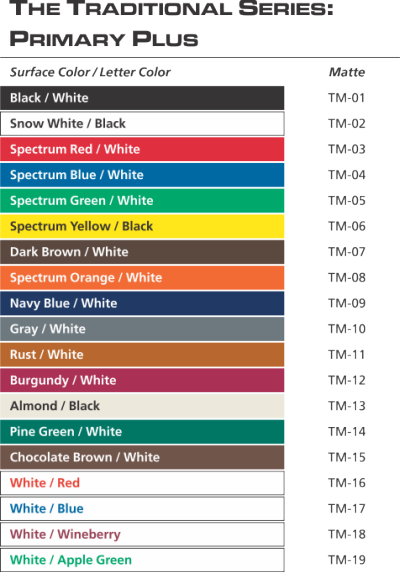

A wide spectrum of the engraving industry's most popular colors, available in Matte finish. (Micro-satin or gloss available as custom only.)

| Material |

Micro-surfaced ABS |

| Sheet Size |

24" x 48" |

| Thickness |

1/16" |

| Usage |

Interior Signage, Personal Identification |

| Cutter |

Rotating carbide |

| Cutting Depth |

.003" |

| Fabrication |

Scores, Shears, Heat bendable, No predrilling |

|

Other Features

|

Bonds, Hot stamps, Silkscreens, Permits detailed engraving |

|

Products listed are readily available in 2-ply 1/16”.

Most products can be produced in 2-ply 1/32” or 1/8” and 3 ply 1/16” or 1/8”. Call for specific details on availability and/or minimum order.

|

Plastic cleaning Recommendations and Tips:

All IPI products are manufactured in the USA and are available only through your Authorized IPI distributor

Note: The information is given in good faith, but no warranty, express or implied, is given.

Distributed by: Jorlink USA, Inc. | Greensboro-NC USA | Tel: (336) 288-1613 | sales@jorlink.com | www.JORLINK.com

Cleaning Recommendations

Tips for cleaning Jorlink's Distributed IPI Plastic materials:

1. As a general rule, IPI recommends using mild soap and water whenever possible.

2. Test a piece of scrap or small area of the material before cleaning entire piece.

3. Use only soft cloths or sponges for cleaning. Do NOT use Brillo®/S.O.S.® pads or steel wool.

4. Use a Q-Tip® to clean small areas.

5. Rinse with warm water.

6. Ultrasonic cleaning is NOT RECOMMENDED for any IPI material.

7. To remove dust from engraved areas, try compressed air before any solvent cleaner.

8. Cleaners with abrasives, such as Comet® brand cleaner, are not recommended.

Some plastic materials such as Red on White are difficult to laser engrave because of the nature of laser heat

and the pigmentation bonding to the bottom lawyer; if the above recommendation fails try the following tips.

IPI Plastics cleaning tips:

Tip # 1: We recommend straight rubbing alcohol, after you should wipe off with damp soft cloth and wipe dry.

Tip # 2: Engrave from the bottom –up less residue, and the laser could be too hot, check setting. Our GCC

Print Driver as other drivers has option of PRINTING from Bottom to Top.

Tip #3: If the above tips do not work, you may need to attempt engraving a second pass on the material to

completely remove the pigments.