Purex Fume Extraction System

GCC teams up with a UK company to offer the Purex fume extraction unit for its full-line LaserPro laser engraving and cutting systems. These Fume Extraction Systems are specifically designed to prevent personnel from inhaling hazardous fumes and dust generated during the process. Applicable to all GCC LaserPro engravers, the Purex Fume Extraction System represents the latest invention in the exhaust extraction and smoke reduction technology for all types of applications. Noise-free operation, high vacuum capacity, compact design and long life expectancy are just a few of its outstanding features. Powered by a maintenance-free, continuous-running turbine, the Fume Extraction System, which is CE-compliant, ensures personnel safety and legal compliance.

Wi-Fi Router

Wi-Fi router allows you to transmit data through a wireless network. It can work with GCC laser engravers and RX II/ Jaguar V cutting plotters through the Ethernet port (not applicable for Japanese users.) Whether you are sending files to multiple GCC machines using one PC or sharing one unit of GCC machines with multiple PCs, this wireless technology can be an excellent helper.

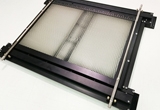

Thin Metal Film Clamping Device

Not only thick metal, but also thin metal films or metal meshes can be handled by the FMC280 laser cutting system. Thin metal films can be easily thermally distorted and its flatness affected by high pressure assisted gas during high power laser cutting process; meanwhile precise focal distance is critical to the quality of laser cutting. The GCC LaserPro team therefore develops the Thin Metal Film Clamping Device to keep thin metal materials flat without curls caused by the high pressure assisted gas and thermal distortion during laser cutting process to maintain the cutting quality. The working area of Thin Metal Film Clamping Device is 458mmx305mm (18”x12”).

Supporting Pin

Relocatable Supporting Pins sustain working piece together with Magnetic Fixtures to reduce laser reflection and residues to the rear side of working media presenting nice cutting quality.

Magnetic Fixture

Arrange Magnetic Fixtures to hold working piece firmly with flexibility to accommodate different cutting paths, the cutting quality is ensured with consistent focal distance between working piece and cutting head.

SmartAIR Ultra Nozzle

SmartAIR Ultra Nozzle delivers assisted gas to media with extended length when cutting thicker metals, result in clear cutting edge.

Rotary Chuck - S290LS/FMC280

Handy rotary chuck to work with cylindrical metal objects like pipes, engineering parts, and even spherical objects with tilt angle. In addition to the standard X, Y, Z axis, the rotary Chuck allows for a fourth axis which rotates the object 360° to allow for engraving and cutting on spherical objects. The diameter range of the to-be-engraved object is 0.5mm to 120mm and the max. length of the object is 410mm. Its maximum weight should not exceed 4kgs.