|

Go Back

CerMark/TherMark Permanence

Whether your mark needs to stand up to direct sunlight, abrasive chemicals, high temperatures, physical abrasion, or salt spray, TherMark offers the most permanent, high contrast, high resolution marks possible which do not damage your substrate. The sections below detail the results of our studies on the permanency of our marks in a variety of extreme environments.

UV Exposure & Weathering

- ASTM D4329 Procedure / Weather Cycle B

- 8 hrs exposure to UV at 70 °C, followed by 4 hrs exposure to condensation at 50 °C 1000 hrs (42 days) correlates to 1 yr of Florida exposure

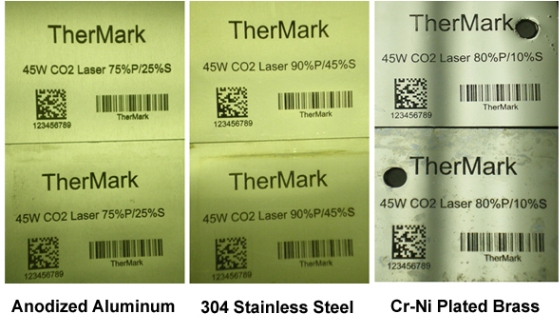

TherMark material was tested on various substrates for 2000 hours. There was no noticeable degradation of the marks (fresh marks on top, UV exposed marks on bottom):

Marks were also tested for extreme UV & Temperature exposure in space.

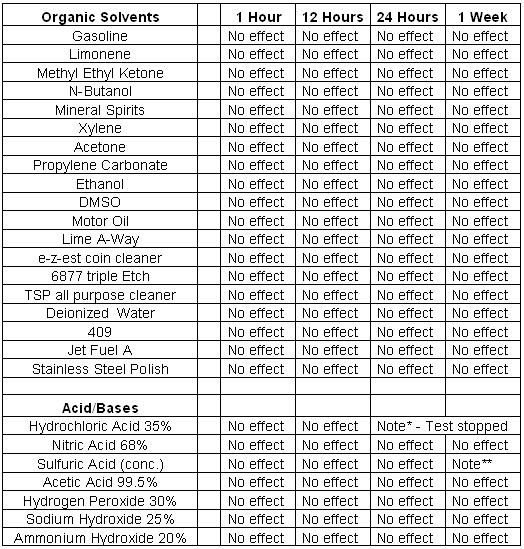

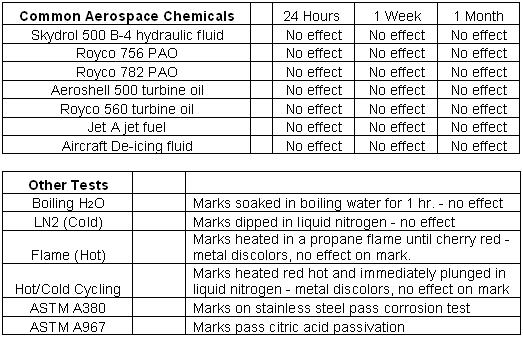

Chemical Resistance

TherMark LMM6000 material was marked on Stainless Steel 304 tags using a CO2 laser then immersed in the following chemicals:

* Hydrochloric acid testing:

- Acid dissolves the steel tag and was not run over 12 hrs.

- After 1 hr. acid dissolved 0.2767 gms of steel tag (4.7%), laser mark was unaffected.

- After 12 hrs. dissolved 1.8057 gms of steel tag (30.6%), laser mark unaffected, now having a distinctly raised feel.

** Sulfuric acid testing:

- Acid discolors at approximately 96 hrs., mark appears slightly discolored.

Temperature Resistance

- The glass frit in TherMark materials melts at approximately 1800°F, providing extreme temperature resistance without discoloration.

Abrasion Resistance

- The glass component of the material ensures the marks are extremely hard and therefore resistant to abrasion assuming they have been correctly bonded. It is generally not possible to remove marks unless the abrasive is also removing the base material.

Salt Spray Tests

- In applications which require salt spray testing, TherMark materials, when bonded with a CO2 laser, are able to produce black marks without the substrate annealing typical with a direct mark from a solid state laser.

The picture shows a 420 stainless steel part that has been marked then tested for corrosion. The salt dip test specification called for the part to be dipped for 20 seconds in a 1% salt solution at a temperature of between 140 & 160°F. The part is then removed for 10 seconds. This cycle is repeated 720 times for total test duration of approximately 6 hours. The picture shows a 420 stainless steel part that has been marked then tested for corrosion. The salt dip test specification called for the part to be dipped for 20 seconds in a 1% salt solution at a temperature of between 140 & 160°F. The part is then removed for 10 seconds. This cycle is repeated 720 times for total test duration of approximately 6 hours.

Customer Testing Disclaimer

The word permanence can mean many different things to customers depending on your perspective. The tests described and the results achieved represent limited validation from internal tests conducted by TherMark and its licensees of certain laser bonding materials on a range of common substrates.

Because of the wide range of material substrates and variability of process settings and equipment, we strongly recommend that customers conduct their own testing to determine that the laser bonding process meets their unique requirements for permanence in a given environment.

It is ultimately the responsibility of our customers to validate the suitability of the marking process for their needs.

Go Back

|