Stack Light Set

The indicator will flash to signal the end of job process and is ideal for working environment where audibility is weak.

Red light stands for “Error”; Green light stands for “ Stand-by”; Yellow light stands for “Machine is working / Insert the pass-through door key”

(This item is available for machine with 5272 V3 Mainboard and afterwards)

SmartVISION Pro CCD

GCC LaserPro utilizes CCD module to enhance productivity as it is able to learn, memorize and locate the printed graphics to perform contour cutting and automatically make adjustments to ensure the material is cut correctly. The LaserPro CCD module allows you to create incredibly accurate laser cuts around images that are print on wood, acrylic, cardstock and more.

Pass-through Door Switch Module

The Pass-through Door Switch Module is designed to activate the laser when the door is open which conforms the CDRH safety required by FDA.

Rotary Chuck

The rotary chuck is a handy …..for engraving on cups, wine glasses, and even spherical objects with tilt angle. In addition to the standard X, Y, Z axis, the rotary Chuck allows for a fourth axis which rotates the object 360° to allow for engraving on cups, wine glasses, and even spherical objects. The diameter range of the to-be-engraved object is 0.5mm to 120mm and the max. length of the object is 410mm. Its maximum weight should not exceed 4kgs.

Rotary Attachment

Allows the laser system to perform at another level! By using the rotary attachment, engraving on cylindrical or round objects is now possible. This option uses a fourth axis to rotate your object 360° to allow engraving on cups, wine glasses or even a baseball with two types of conical fixture available. The minimum/maximum diameter and length of the working object is 90/180mm and 450mm respectively. Its maximum weight should not exceed 4kgs.

Purex Fume Extraction System

GCC teams up with a UK company to offer the Purex fume extraction unit for its full-line GCC LaserPro laser engraving and cutting systems. Purex is specifically designed to prevent personnel from inhaling hazardous fumes and dust generated during the process. Noise-free operation, high vacuum capacity, compact design, and long life expectancy, the Purex is CE-compliant that represents the latest invention in exhaust extraction and smoke reduction technology for all types of applications.

Air Compressor

A specially designed Air Compressor, by using an oil-less diaphragm, helps you eliminate the harmful and damaging side effects of moisture on the laser optics. In addition, it provides the optimal air pressure when laser engraving and cutting to blow away vaporized particles and prevent overheating, keeping lenses and mirrors clean for longer laser life.

SmartGUARD™ Fire Alarm (Patented)

Laser cutting and engraving operation using the SmartGUARD Fire Alarm assures optimum safety. When there is a malfunction, the alarm system will be active and shut-down the operation system immediately.

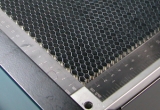

Honeycomb Table

The honeycomb table is an ideal tool for laser cutting, especially when cutting materials into small pieces. It lifts the work piece off the work table from hitting by laser reflection while supports it with honeycomb cell design. The dust and vapor created during laser cutting are then taken away effectively through the honeycomb cell by down vacuum funnel exhaust. Rather than handling rigid materials, honeycomb table also helps to fix flexible materials with the aid of down vacuum to keep constant focus distance and consistent cutting result. A clean and better cutting quality is achieved from this technique.