External Interface Control Board

The External Control Interface Board is an optional item that allows users to set up GCC laser machines for communication with external devices such as odor reduction units, robot arms and others via a 5V or 12V signal to form an automatic production line. Another useful practice applies in certain working environments when users are required to set up an extra remote interlock control or when laser machines are allowed to be switched off if a security device is triggered.

Rotary Attachment

Allows the laser system to perform at another level! By using the rotary attachment, engraving on cylindrical or round objects is now possible. This option uses a fourth axis to rotate your object 360° to allow engraving on cups, wine glasses or even a baseball with two types of conical fixture available. The minimum/maximum diameter and length of the working object is 90/180mm and 450mm respectively. Its maximum weight should not exceed 4kgs.

*Please note that the Rotary Attachment is not able to work with AAS module at the same time.

SmartAIR™ Fine Nozzle

The optional SmartAIR Fine Nozzle is recommended for engraving or cutting thin materials such as textile. The smaller caliber nozzle is positioned closer to the object for a concentrated blast directed over a small area to eliminate burning on the cutting edge. The perfectly-vertical design of the SmartAIR Fine Nozzle produces a concentrated airflow to blow away dust and unwanted residue, leaving a clean product surface.

Purex Fume Extraction System

GCC teams up with a UK company to offer the Purex fume extraction unit for its full-line LaserPro laser engraving and cutting systems. These Fume Extraction Systems are specifically designed to prevent personnel from inhaling hazardous fumes and dust generated during the process. Applicable to all GCC LaserPro engravers, the Purex Fume Extraction System represents the latest invention in the exhaust extraction and smoke reduction technology for all types of applications. Noise-free operation, high vacuum capacity, compact design and long life expectancy are just a few of its outstanding features. Powered by a maintenance-free, continuous-running turbine, the Fume Extraction System, which is CE-compliant, ensures personnel safety and legal compliance.

Air Compressor

A specially designed Air Compressor for laser engravers, by using an oil-less diaphragm, you help eliminate the harmful and damaging side effects of moisture on the laser optics. Also, provides the optimal air pressure your laser needs to blow away vaporized particles and helps prevents overheating. A must to keep lenses and mirrors clean to promote longer laser life.

SmartGUARD™ Fire Alarm (Patented)

Laser cutting and engraving operation using the SmartGUARD Fire Alarm assures optimum safety. When there is a malfunction, the alarm system will be active and shut-down the operation system immediately.

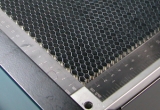

Honeycomb Table

The honeycomb table is an ideal tool for laser cutting, especially when cutting materials into small pieces. It lifts the work piece off the work table from hitting by laser reflection while supports it with honeycomb cell design. The dust and vapor created during laser cutting are then taken away effectively through the honeycomb cell by down vacuum funnel exhaust. Rather than handling rigid materials, honeycomb table also helps to fix flexible materials with the aid of down vacuum to keep constant focus distance and consistent cutting result. A clean and better cutting quality is achieved from this technique.

| Mercury III |

|

| Max. Part Size(W x L x H) |

All doors closed |

27 x 19 x 6.5 in. (685 x 482 x 165 mm) |

| All doors open |

27 x ∞ x 6.5 in. (685 x ∞x 165 mm) |

| Table Specs |

31.1 x 20.9 in. (790 x 530 mm), Aluminium |

| Dimensions (WxDxH) |

44.3 x 28.3 x 39.6 in. (1125 x 720 x 1005 mm) |

|

| Shipping DIM's |

Crate 463 Lbs, GW 49"x34"x51" , Class 125 |

| Laser Source |

12, 25, 30, 40, 60W

|

| Cooling |

Air-cooled, Operating environment temperature 15°- 30°C (60°- 86°F) |

| Drive |

Closed-loop DC Servo Control |

| Throughput* |

166.3 in2 / hr (1072.8 cm2 / hr) |

| Speed Control |

Adjustable from 0.1~100% of 42 IPS

(Up to 16 color-linked speed settings per job) |

| Power Control |

Adjustable from 1-100% (Up to 16 color-linked power settings per job) |

| Engraving capability |

256-level gray scale image processing capability |

| Distance Accuracy |

0.254mm or 0.1% of move, whichever is greater |

| Z-Axis Movement |

Automatic |

| Focus Lens |

Standard 2.0", optional 1.5", 2.5" & 4.0" available |

| Resolution (DPI) |

Available125, 250, 300, 380, 500, 600,760,1000, 1500 |

| Computer Interface |

10 Base-T Ethernet, Full speed 2.0 USB |

| Compatible Operating Systems |

MS Windows |

| Display Panel |

4-line LCD panel showing current file name, total working time,

laser power, engraving speed, file(s) loaded into memory buffer,

setup and diagnostic menus. |

| Safety |

Class I Laser Product Compliant with EN60825,

Class II Laser Product Compliant with CDRH

2006/42/EC Machinery Directive Compliance |

| Auto Focus |

V |

| Red Dot Pointer |

V |

| Pass Through Doors |

V |

| 3D and Stamp Mode |

V |

| Operation Voltage |

100-240VAC, 50-60Hz Auto Switching, Max. 15A |

| Fume Extraction System |

External exhaust system with minimum flow rate 215m3/h is required,

2-inch connection port on the back of machine |

*Speed is not equal throughput. See dealer or visit http://www.gccworld.com for more details.

Specifications are subject to change without prior notice.

*The flow rate is determined by a default fume extraction system; the flow rate may vary due to a di fferent fume extraction system.

A Pictaure Conveys a Thousand Words

Glass vs. metal laser tube