Big Laser Time Savings with Roll to Roll Accessory

GCC, a global forefront equipment-manufacturing provider in the visual-tech industry, is pleased to announce the new optional Roll to Roll Autofeeder device, available for GCC LaserPro Spirit & Spirit LS.

GCC, a global forefront equipment-manufacturing provider in the visual-tech industry, is pleased to announce the new optional Roll to Roll Autofeeder device, available for GCC LaserPro Spirit & Spirit LS.

The Roll to Roll Autofeeder unit is a superior user-friendly optional item that can be used in tandem with GCC LaserPro Spirit or Spirit LS models to form an automated engraving system when working with rolled material. For instance, if used with Heat transferable material such as PureFlex or SEF heat transfer papers, the laser can produce very exquisite and delicate patterns which can be heat pressed directly without the need for weeding. The Roll to Roll Autofeeder is the essential solution to mass production requirements.

Purex Fume Extraction System

GCC teams up with a UK company to offer the Purex fume extraction unit for its full-line LaserPro laser engraving and cutting systems. These Fume Extraction Systems are specifically designed to prevent personnel from inhaling hazardous fumes and dust generated during the process. Applicable to all GCC LaserPro engravers, the Purex Fume Extraction System represents the latest invention in the exhaust extraction and smoke reduction technology for all types of applications. Noise-free operation, high vacuum capacity, compact design and long life expectancy are just a few of its outstanding features. Powered by a maintenance-free, continuous-running turbine, the Fume Extraction System, which is CE-compliant, ensures personnel safety and legal compliance.

Flame Sprinkler System

Laser cutting and engraving operations using the flame sprinkler system protects the operator, machine, and the work products from potential fire hazards. During the engraving process, flaming may occur when working with combustible or easily-flammable materials, such as paper or wood. The flame sprinkler system is an optional item that automatically ejects gas to extinguish flames when they reach 68°C/155°F moments after the onset of the fire.

Wi-Fi Router

Wi-Fi router allows you to transmit data through a wireless network. It can work with GCC laser engravers and RX II/ Jaguar V cutting plotters through the Ethernet port (not applicable for Japanese users.) Whether you are sending files to multiple GCC machines using one PC or sharing one unit of GCC machines with multiple PCs, this wireless technology can be an excellent helper.

Rotary Chuck

The rotary chuck is a handy …..for engraving on cups, wine glasses, and even spherical objects with tilt angle. In addition to the standard X, Y, Z axis, the rotary Chuck allows for a fourth axis which rotates the object 360° to allow for engraving on cups, wine glasses, and even spherical objects. The diameter range of the to-be-engraved object is 0.5mm to 120mm and the max. length of the object is 410mm. Its maximum weight should not exceed 4kgs.

*Please note that the Rotary Attachment is not able to work with AAS module at the same time.

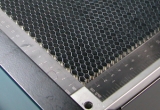

Aluminum Grid Cutting Table

The aluminum grid cutting table is an ideal pal for laser cutting. It lifts the work piece off the work table from hitting by laser reflection while supports it with reinforced aluminum grid design. The dust and vapor created during laser cutting are then taken away effectively through the grid by down vacuum exhaust (suggested using SmartBOX™ together). Rather than handling rigid materials, aluminum grid cutting table also helps to fix flexible materials with the aid of down vacuum SmartBOX™ to keep constant focus distance and consistent cutting result. A clean and better cutting quality is achieved from this technique.

External Interface Control Board

The External Control Interface Board is an optional item that allows users to set up GCC laser machines for communication with external devices such as odor reduction units, robot arms and others via a 5V or 12V signal to form an automatic production line. Another useful practice applies in certain working environments when users are required to set up an extra remote interlock control or when laser machines are allowed to be switched off if a security device is triggered.

AAS Contour Cutting Device (Patented)

Developed by GCC LaserPro, AAS is an exceptionally user-friendly operation which offers accurate and faultless contour cutting by automatically tracking the position of graphics.

Note: Working area and engraving speed will be reduced when AAS module is installed.

External Signal Indicator

The indicator will flash to signal the end of job process and is ideal for working environment where audibility is weak.

SmartBOX™

An innovative technology that integrates the ventilation box with a honeycomb table or Aluminum grid cutting table. The result is not only a precise cut with sharp edges, but also a clean laser table to work on.

Roll to Roll Autofeeder

The Roll to Roll Autofeeder unit is a great optional item that can be used in tandem with Spirit or Spirit LS, or Spirit GLS model to form an automated engraving system when working with rolled material. For instance, if used with Heat transferable materials, the laser can produce very fine and delicate patterns which can be heat pressed directly without the need for weeding. The Roll to Roll Autofeeder is the essential solution to mass production requirements.

* The width of material loading is limited to 600mm (23.6”).

Rotary Attachment

Allows the laser system to perform at another level! By using the rotary attachment, engraving on cylindrical or round objects is now possible. This option uses a fourth axis to rotate your object 360° to allow engraving on cups, wine glasses or even a baseball with two types of conical fixture available. The minimum/maximum diameter and length of the working object is 90/180mm and 450mm respectively. Its maximum weight should not exceed 4kgs.

*Please note that the Rotary Attachment is not able to work with AAS module at the same time.

SmartAIR™ Fine Nozzle

The optional SmartAIR Fine Nozzle is recommended for engraving or cutting thin materials such as textile. The smaller caliber nozzle is positioned closer to the object for a concentrated blast directed over a small area to eliminate burning on the cutting edge. The perfectly-vertical design of the SmartAIR Fine Nozzle produces a concentrated airflow to blow away dust and unwanted residue, leaving a clean product surface.

Dust Prevention Window

When the laser system is on duty, it will bring a lot of dust result from the material and it will contaminate the lenses and mirrors. Dust Prevention Window can keep lenses and mirrors clean to promote longer laser life and increase the effect of air induction.

Purex Fume Extraction System

GCC teams up with a UK company to offer the Purex fume extraction unit for its full-line LaserPro laser engraving and cutting systems. These Fume Extraction Systems are specifically designed to prevent personnel from inhaling hazardous fumes and dust generated during the process. Applicable to all GCC LaserPro engravers, the Purex Fume Extraction System represents the latest invention in the exhaust extraction and smoke reduction technology for all types of applications. Noise-free operation, high vacuum capacity, compact design and long life expectancy are just a few of its outstanding features. Powered by a maintenance-free, continuous-running turbine, the Fume Extraction System, which is CE-compliant, ensures personnel safety and legal compliance.

Air Compressor

A specially designed Air Compressor for laser engravers, by using an oil-less diaphragm, you help eliminate the harmful and damaging side effects of moisture on the laser optics. Also, provides the optimal air pressure your laser needs to blow away vaporized particles and helps prevents overheating. A must to keep lenses and mirrors clean to promote longer laser life.

SmartGUARD™ Fire Alarm (Patented)

Laser cutting and engraving operation using the SmartGUARD Fire Alarm assures optimum safety. When there is a malfunction, the alarm system will be active and shut-down the operation system immediately.

Honeycomb Table

The honeycomb table is an ideal tool for laser cutting, especially when cutting materials into small pieces. It lifts the work piece off the work table from hitting by laser reflection while supports it with honeycomb cell design. The dust and vapor created during laser cutting are then taken away effectively through the honeycomb cell by down vacuum funnel exhaust. Rather than handling rigid materials, honeycomb table also helps to fix flexible materials with the aid of down vacuum to keep constant focus distance and consistent cutting result. A clean and better cutting quality is achieved from this technique.

MAlubeGCC10ML Special lubricating greases

Recommended Lubricant for X-axis Rails

on GCC Laser Machine Models: Spirit

SLS, GLS, SGLS-Hyb,S290LS, FMC 270